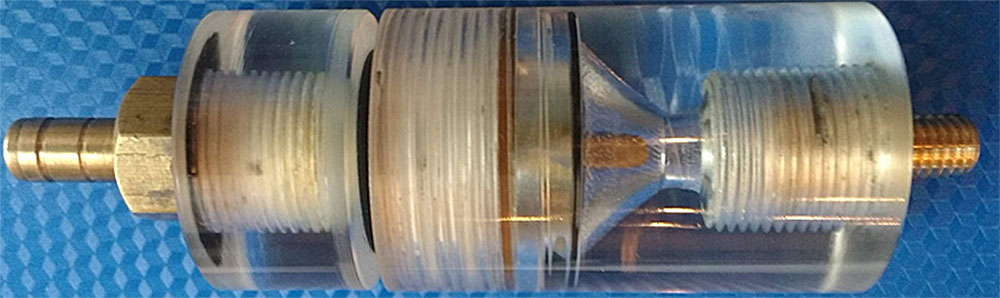

Cavitation magnetic activator of fuel

The project relates to the technological use of the phenomenon of hydrodynamic cavitation and can be used in various industries, in particular in processes occurring in liquid media, for example, when activating liquids and liquid fuels (gasoline, diesel fuel, kerosene).

The proposed cavitation device for treating liquid or fuel (gasoline, diesel, kerosene, etc.) ensures the activation of fluid due to hydrodynamic cavitation and magnetic effects. Activated liquid fuel has increased energy burning rates.

The fuel cavitator in the car's power system provides:

- fuel economy,

- increase engine power,

- reduction of harmful emissions.

The challenging problem of increasing the efficiency and environmental compatibility of internal combustion engines can be solved by the use of portable fuel cavitators and fuel activators whose function is to improve the performance of fuel for the ICEs, in order to reduce fuel consumption by up to 30%, increase the environmental friendliness and engine power, using hydrodynamic cavitation and magnetic activators.

The cavitation magnetic activator of fuel allows to activate fuel due to hydrodynamic cavitation and magnetic influence. The device operates in a wide temperature range.

Activated liquid fuel has increased energy burning rates. This fuel is fully combusted in the internal combustion engine chamber with maximum efficiency, does not wash off the grease film from the friction pairs and does not emit exhaust gases into the atmosphere.

The emulsion obtained in such a device does not demix for a long time due to intense cavitational mixing at the molecular level.

Target audience:

- automotive market (car owners, car dealerships),

- refineries.

At present, a prototype fuel cavitator for passenger cars with engine capacity of 1.2 – 1.6 liter is designed, patented and manufactured.